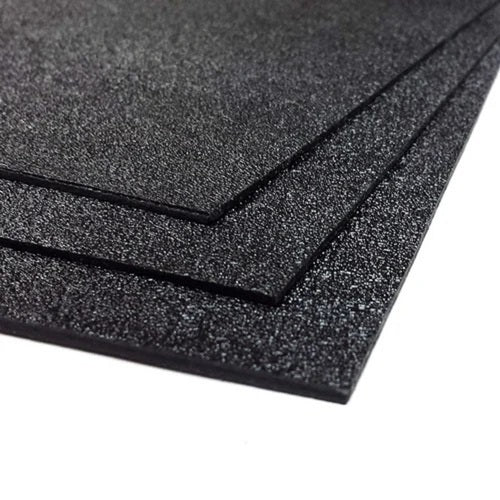

ABS

Low-cost plastic with exceptional impact resistance, easy to machine and thermoform.

ABS

ABS is a plastic material with excellent impact resistance, machinability, and thermoforming characteristics. It is an excellent choice for machine housings, shop fittings, and point-of-sale displays where impact resistance or durability is required.

ABS plastic is available in general-purpose, mechanical, flame-resistant, UV-resistant, orthopedic, FDA-compliant, and scratch-resistant forms, in a wide variety of textures and colors. For ABS chemical resistance, see our table.

Collapsible content

Typical properties

Physical properties

Mechanical properties

Thermal properties

Electrical properties

Optical properties

Other properties

Contact us for customized solutions

At A&C Global Procurement Solutions, we are committed to providing you with the best service. If you have any questions about our aluminum plates or need help selecting the most suitable option for your projects, please don't hesitate to contact us.

Fill out the form below with your information, and one of our specialists will provide you with the personalized attention you need. We're here to help you find the ideal solution!

Contact form

Frequently Asked Questions

What is ABS material?

ABS is an affordable plastic known for its excellent impact resistance, ease of machining and thermoforming.

What are the disadvantages of ABS material?

- Standard grades have limited weather resistance.

- It becomes brittle at low temperatures.

- Not suitable for use at high temperatures.

- Low strength and stiffness.

- Limited chemical resistance.

What are the advantages of ABS material?

- Impact resistant.

- Easy to machine and thermoform.

- Easy to join with adhesives.

- Low cost.

Is ABS safe for food?

Some grades of ABS meet FDA regulations for direct contact with food.